Contents

Introduction to AC Power Measurement

In alternating current circuits, the instantaneous power varies continuously as the voltage and current varies while going through a cycle. In this case the power at any instant is given by:

p(t) = v(t) x i(t)

Where, p(t), v(t) and i(t) are the values of instantaneous power, voltage and current respectively.

Therefore, if both voltage and current can be assumed to be sinusoidal, with the current lagging the voltage by phase-angle Φ, then

v(t) = Vmsin wt

Recommended: The Ultimate Guide to Electrical Maintenance

i(t) = Imsin (wt-Φ)

Where Vm and Im are peak values of voltage and current respectively and w is the angular frequency, thus the instantaneous power is given by:

p(t) = VmImsin wt sin (wt-Φ)

Don’t miss out on key updates, join our newsletter List

Using trigonometric identity

sin αsin β = ½ [cos (α-β) – cos (α+β)]

p(t) = ½ x VmIm[cos {wt-(wt-Φ)} – cos {wt +(wt –Φ)}]

p(t) = ½ x VmIm[cos Φ – cos (2wt-Φ)]

The instantaneous and average power corresponding to the voltage v(t) = Vmsin wt and current i(t) = Im sin (wt – Φ) signals can be obtained by integrating the instantaneous power over one cycle of the sinusoidal signal. We know that

T (periodic time) represents one cycle of sinusoidal signals. Then the average power Pav is given by the integral of the instantaneous power p(t) over one cycle.

Since the second integral is equal to zero and cos Φ is a constant, we have

Where, V and I are rms value of voltage and current respectively and cos Φ is the power factor of the load.

It is clear that, the involvement of the power factor term cos Φ in the expression for power circuit shows that AC power cannot be measured by simply connecting an Ammeter and Voltmeter as with the DC power measurement. You therefore need a wattmeter with inbuilt features for taking into account the power factor for measurement of power in AC circuits.

Electrodynamometer-type Wattmeter

Basic Constructional Features of Electrodynamometer-type Wattmeter

This instrument has two coil types connected in different ways to the same circuit of which the power is to be measured.

- Fixed coil system

- Moving coil system

Fixed Coil System

The fixed coils are connected in series with the load so as to carry the same current as the load. The fixed coils are thus termed to as the current coils (CC) of the wattmeter. The main magnetic field is produced by these fixed coils. This coil is divided into two sections so as to provide more uniform magnetic field near the center and allow the placement of the instrument moving shaft.

Moving coil system

The moving coil is connected across the load and carries a current proportional to the voltage. Since the moving coil carries a current proportional to the voltage it is called the voltage coil or the pressure coil (PC) of the wattmeter. The moving coil is entirely embraced by the pair of fixed coils. A high value non-inductive resistance is connected in series with the voltage coil to restrict the current through it to a small value, and also to ensure that the voltage coil current remains as much as possible in phase with the load voltage.

Operational of Electrodynamometer-type Wattmeter

Let’s consider the schematic circuit of an electrodynamometer-type wattmeter being used for power measurement in a circuit.

Where,

V = voltage to be measured (rms)

I = current to be measured (rms)

ip = Pressure coil (PC) instantaneous current

ic = instantaneous current coil (CC) current

Rv = external resistance connected with pressure coil

rp = Pressure coil (PC) resistance

Rp = resistance of pressure coil circuit (rp + Rv)

M = mutual inductance between the current coil and pressure coil

ϴ = angle of deflection of the moving system

w = angular frequency of supply in radians per second

Φ = phase-angel lag of current I with respect to voltage V

The instantaneous torque of the electrodynamometer wattmeter is given by the formula

Instantaneous value of voltage across the pressure coil (PC) circuit is

If the pressure resistance can be assumed to be very high, the whole pressure coil can be assumed to be behaving like a resistance only. The current ip in the pressure coil therefore can be assumed to be in phase with voltage vp, and its instantaneous value is

Assuming that the pressure-coil resistance is sufficiently high to prevent branching out of any portion of the supply current towards the pressure coil, the current coil current can be written as

The presence of the term contain 2w, t indicates the instantaneous torque varies at twice the frequency of the voltage and current.

Average deflecting torque over complete cycle is given by:

With spring constant, the controlling torque provided by the spring for a final steady-state deflection is given by

Tc = Kϴ

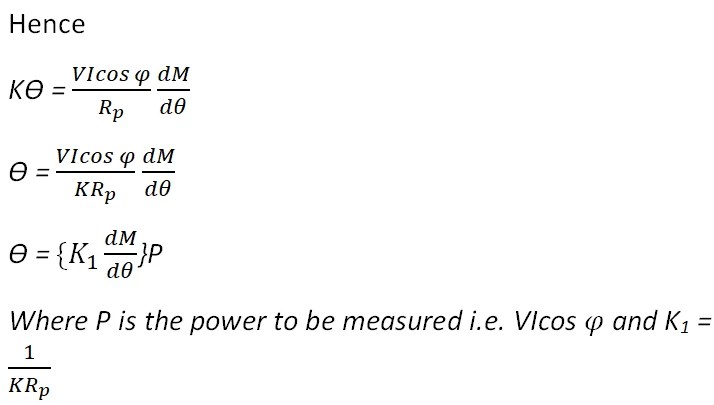

Under steady-state condition, the average deflecting torque will be balanced by the controlling torque provided by the spring. Thus at balanced condition

Tc = Td

Steady-state deflection ϴ is thus found to be an indication of the power to be measured.

Errors in Electrodynamometer-type Wattmeter

Error due to Pressure-coil inductance

In our discussions above, we presumed that the pressure coil circuit is purely resistive however in practice; the pressure coil will have certain inductance along with the resistance. Due to inherent inductance of the pressure coil circuit, the current and voltage in the pressure coil will no longer be in phase; rather the current through the pressure coil will lag the voltage across it by a certain angle given by:

Where,

L = the inductance of the pressure coil

rp = resistance of the pressure coil

w = angular velocity of supply in radian per second

Rp = Resistance of pressure coil circuit (PC resistance + Rv)

Φ = phase-angle lag of current I with respect to voltage V

From the phasor diagram above, the phase angle between the pressure coil and current coil is

Φ1 = Φ –α

Therefore true power can thus be obtained from the actual wattmeter reading using the correction factor CF as

True power indication = CF x Actual wattmeter reading

A wattmeter can be compensated for pressure coil inductance by connecting a preset value of capacitance across a certain portion of the external resistance connected in series with the pressure coil as illustrated in the figure below:

Error due to Pressure coil capacitance

The voltage or pressure coil circuit may have inherent capacitance besides inductance. This capacitance effect is mainly due to inter-turn capacitance of the winding and external series resistance. The effect of stray capacitance of the pressure coil is opposite of that due to inductance. Hence, the wattmeter reads low on lagging power factor and high on leading power factors. Actual reading of the wattmeter thus needs to be corrected by the corresponding correction factors to obtain the true reading. The effect of capacitance and inductance varies with variable frequency of supply.

Error due to connection

There are two alternate methods of connections of a wattmeter to the circuit for measurement of power as illustrated below:

In Figure (e), the pressure coil is connected across the supply, thus the pressure coil (PC) measures the voltage across the load, plus the voltage drop across the current coil (CC). The wattmeter reading in this case will include power loss in current coil along with the power consumed by the load.

Wattmeter reading = Power consumed by load + Power loss in current coil (CC)

In the Figure (f), the current coil is connected to the supply side; therefore it carries load current plus the pressure coil current. Thus, wattmeter reading in this case includes in addition, to power consumed by the load, the power loss in the pressure coil.

Wattmeter reading = Power consumed by load + Power loss in the pressure coil (PC)

Note that, if the load current is small, power loss in the current coil is small and hence the connection of Figure (e) will introduce comparatively lesser error in measurement.

Alternatively, when the load current is large, current branching through the pressure coil is relatively small and error in measurement will be less if connection of Figure (f) is used.

The errors of branching out of current through the pressure coil can be minimized by employing a compensating coil as illustrated below:

In the compensated connection, the current coil consists of two windings, each having the same number of turns. The two windings are made as far as possible identical and coincident. One of the two windings (CC) is made of heavy wire that carries the load current plus the current for the pressure coil. The other winding (i.e. compensating coil-CoC) which is connected in series with the pressure coil, uses thin wire and carries only the current to the pressure coil. This current in the compensating coil is however, in direction opposite to the current in the main current coil, creating a flux that opposes the main flux. The resultant magnetic field is thus due to the current coil only, effects of pressure coil current on the current coil flux mutually cancelling out each other. Hence error due to pressure coil current flowing in the current coil is cancelled out and the wattmeter indicates the correct power.

Eddy-current Errors

Without adopting adequate precautions, eddy currents may be induced in metallic parts of the instruments, even within the thickness of the conductors by alternating magnetic field of the current coil. These magnetic fields produce spurious magnetic fields that distort the magnitude and phase of the main current coil magnetic field thereby introducing an error in measurement of power. Stranded conductors are recommended for the current coil to restrict generation of eddy-currents within the thickness of the conductors.

Error due to vibration of the moving system

The instantaneous torque on the moving system varies cyclically at twice the frequency of the voltage and current. If any part of the moving system, such as the spring or the pointer has natural frequency close to that of the torque pulsation, then accidental resonance may take place, in such case, the moving system may vibrate with considerable amplitude. These errors due to vibration may be prevented by designing the moving elements to have natural frequencies much further away from twice the frequency of the supply voltage.

Stray magnetic field errors

The operating field in electrodynamometer-type instruments is weak therefore care must be taken to protect these instruments from external magnetic fields. Therefore these instruments should be shielded against effects of magnetic fields. Laminated iron shields are used in portable laboratory instruments, while steel casings are provided as shields in switch gear mounted wattmeter. However for precision wattmeters, they are not provided with metal shields for that will introduce errors due to eddy-currents, and also some dc error due to permanent magnetization of the metal shield under the influence of external magnetic field.

Precision wattmeters are manufactured to have astatic system i.e. they are constructed with two similar sets of fixed and moving coils mounted on the same shaft. The pair of fixed coils is so connected that their magnetic fields are opposition. In the same way, the pair of the moving coils is also connected to produce magnetic fields in opposite directions. This makes the deflecting torque acting on the two moving coils to be in the same direction. Deflection of the pointer is thus due to additive action of the two moving coils. However since the two fields in the two pair of fixed and moving coils are in opposition, any external uniform field will affect the two sets of pairs differently. The external field will reduce the field in one coil and will enhance the field in the other coil by identical amount. Thus, the deflecting torque produced by one coil is increased and reduced by an equal amount in the other coil. This makes the net torque an account of the external magnetic field to zero.

Temperature Errors

Temperature changes may affect the accuracy of wattmeter by altering the coil resistances. Temperature change may be due to change in room temperature or due to heating effects in conductors with flow of current. Change in temperature may also affect the spring stiffness, thereby introducing error in the deflection process. High-precision instruments are fitted with temperature compensating resistors that tend to neutralize the effects of temperature variation.

Induction-type wattmeter

Induction-type wattmeters principle of operation is based on mutual induction. They can only be used for measurement of AC power in contrast to electrodynamometer-type wattmeters that can be employed for power measurement in both AC and DC circuits, in addition, induction type wattmeters in contradiction to electrodynamometer type wattmeters, can be used only with circuits having relatively steady values of frequency and voltages.

Basic Constructional Features of Induction-type Wattmeter

Induction-type wattmeters have two laminated iron-core electromagnets. One of the electromagnets is excited by the load current, and the other by a current proportional to the voltage of the circuit in which the power is to be measured. The upper magnet which is connected across the voltage to be measured is termed to as the shunt magnet; whereas the other electromagnet connected in series with the load to carry the load current is called the series magnet. A thin aluminium disc mounted in the space between the two magnets is acted upon by a combined effect of fluxes coming out of the two electromagnets.

The two voltage coils connected in series are wound in such a way that both of them send flux through the central limb. Copper shading bands fitted on the central limb of the shunt makes the flux coming out of the magnet lag behind the applied voltage by 90°.

The series magnet houses two small current coils in series. These are wound in a way that the fluxes they create within the core of the magnet are in the same direction.

Note it has been established that the average torque produced by this instrument is proportional to the power in the circuit.

Differences between Dynamometer-type wattmeter and Induction-type wattmeter

Table 1: Differences between Electrodynamometer wattmeter and Induction-type wattmeter

| Electrodynamometer-type wattmeter | Induction-type wattmeter |

Schematic diagram of Electrodynamometer-wattmeter |  Schematic diagram of Induction-type wattmeter |

| The current coil is split in two parts, but a single pressure coil is used | Both current and pressure coils are split into two parts each, placed on each of two arms of the two magnets |

| Pressure coil is the moving coil | None of the coils are moving, rather there is an aluminium disc placed between the two electromagnets, that moves |

| Pointer is attached with the moving (pressure coil) | Pointer is attached with the aluminium disc |

| This instrument can be used for measurement of power both in AC as well as DC circuits | Can only be used for measurement of power in AC circuits |

| Fluid friction damping is used | Eddy current damping is used |

| Can be used in circuits even with fluctuating frequency and voltage | Can only be used in circuits having relatively steady values of frequency and voltage |

| Both the coils are air cored | Both the coils are mounted on laminated iron core |

AC Power Measurement in Polyphase Systems

Blondel’s Theorem

The theorem states that ‘’in an n-phase network, the total power can be obtained by taking the summation of the n-wattmeters so connected that current elements of the wattmeters are each in one of the n lines and the corresponding voltage element is connected between that line and a common point’’.

Let’s consider the following cases of measuring power in Polyphase systems.

Three-Wattmeter Method

Three-Phase Three-Wire Systems

Wattmeter connection for the measurement of power in a 3-phase 3-wire system is shown below:

The current coils of the three wattmeters, W1, W2 and W3 are connected to the three lines R, Y, and B. Potential coils (PC) of the three wattmeters are connected to the common point C. The potential at the point C may be different from the neutral point (N) potential of the load.

Power consumed by the load

P = VRN x IR + VYN x IY + VBN x IB equation (a)

Reading of wattmeter W1, P1 = VRC x IR

Reading of wattmeter W2, P2 = VYC x IY

Reading of wattmeter W3, P3 = VBC x IB

Now, if the voltage difference between the nodes C and N is taken as

VCN = VC-VN

Then we have

VRN = VR – VN = VR – VC + VC-VN = VRC + VCN

VYN = VY –VN = VY –VC + VC-VN = VYC + VCN

VBN = VB-VN = VB-VC +VC –VN = VBC +VCN

Sum of the three wattmeter readings can now be obtained as:

P1 + P2 +P3 = (VRN –VCN) x IR + (VYN-VCN) x IY + (VBN-VCN) x IB

= VRN x IR + VYN x IY +VBN x IB – VCN (IR +IY +IB)

Applying Kirchhoff’s current law at node N, (IR +IY +IB) = 0

Thus the sum of the wattmeter readings

P1 + P2 + P3 = VRN x IR +VYN x IY + VBN x IB equation (b)

Comparing this equation (b) with equation (a) it is observed that sum of the three individual wattmeter readings indicate the power consumed by the load

Three-Phase Four-Wire System

The wattmeter connection for measurement of power in a 3-phase 4-wire system is shown below:

In this particular case, the common point of the three pressure coils (PC) coincides with the neutral N of the system. Voltage across each potential coils is thus, effectively the per-phase voltages of the corresponding phases. Current through the current coils of the three wattmeters are the phase currents of the corresponding phases.

Sum of the three wattmeter readings in this case will be

P1 + P2 + P3 = VRN x IR + VYN x IY + VBN x IB

This is the exactly same as the power consumed by the load.

Two-Wattmeter Method

This is the most common method of measuring three-phase power. It is particularly useful when the load is unbalanced.

Star-connected System

The connection of a star-connected 3-phase load is shown below:

The current coils of the wattmeters are connected in lines R and B, and their voltages are connected between the lines R and Y, and B and Y respectively.

Power consumed by the load

P = VRN x IR + VYN x IY + VBN x IB equation 1a

Reading of wattmeter W1, P1 = VRY x IR = (VRN –VYN) x IR

Reading of wattmeter W2, P2 = VBY x IB = (VBN – VYN) x IB

Summation of the two wattmeter readings

P1 + P2 = (VRN –VYN) x IR + (VBN –VYN) x IB

= VRN x IR + VBN x IB –VYN x (IR + IB) equation 1b

From Kirchhoff’s law, summation of currents at node must be zero, i.e.

IR + IY + IB = 0

IR + IB = -IY

From equation 1 b, we can re-write

P1 + P2 = VRN x IR + VYN x IY + VBN x IB

Therefore, we can conclude that the sum of the two wattmeter readings is equal to the total power consumed by the load. This is irrespective of the fact that, the load is balanced or not.

Delta-connected System

Two wattmeters can also be used for measurement of total power in a three-phase delta connected system.

Let’s consider the connections in a delta-connected three-phase load show below:

The current coils of the wattmeters are connected in lines R and B, and their voltage coils are connected between lines R and Y, and B and Y respectively.

Power consumed by the load

P = VRB x IR + VYR x IY + VBY x IB equation 2a

Reading of wattmeter W1, P1 = -VYR (IR – IY)

Reading of wattmeter W2, P2 = VBY x (IB – IR)

Summation of the two wattmeters readings

P1 + P2 = -VYR x (IR – IY) + VBY x (IB – IR)

= VYR x IY + VBY x IB – IR x (VYR + VBY) equation 2b

From Kirchhoff’s voltage law, summation of voltage drop across a closed loop is zero i.e.

VYR + VBY + VRB = 0

VYR + VBY = -VRB

Hence from equation 2a, we can re-write

P1 + P2 = VRY x IY + VBY x IB + VRB x IR

Thus, the sum of the two wattmeter readings is equal to the total power consumed by the load. This again, is irrespective of fact whether the load is balanced or not.

Related: Power Measurements in DC Circuits

Reactive Power Measurements

If V and I are the rms value of the voltage and current in a single-phase circuit and Φ is the phase-angle difference between them, then the active power in the circuit is

VIcos Φ

The active power is obtain by multiplying the voltage by the component of current which is in phase with the voltage (that is cos Φ).

The component of current which is 90° out of phase with the voltage (i.e. Isin Φ) is called the reactive component of current and the product VIsin Φ is called the reactive power.

The measurement of reactive power along with the active power is sometimes imperative, since the phase-angle Φ of the circuit can be obtained from the ratio:

The same wattmeter that is employed for the measurement of active power can also be used for the measurement of reactive power with the slight modifications.

Noticing the fact that sin Φ = cos (90 – Φ), the wattmeter may so connected that the current coil carries the load current and the voltage coil should have a voltage that is 90° out of phase with the actual voltage of the circuit. Under these conditions, the wattmeter will read:

VI cos (90 – Φ) or VI sin Φ

In single-phase measurements, the pressure coil circuit may be made to behave as largely inductive by inclusion of external inductors, in series with it. This will cause the pressure coil current to lag behind the voltage by 90°, and thus the wattmeter read

VI cos (90 – Φ) = VI sin Φ = Reactive power

For the measurement of reactive power in a circuit with a balanced 3-phase load, a single wattmeter can be used with suitable connections as illustrated below in Figure 1(e).

The phasor IB represents the current flowing through current coil (CC) of the wattmeter. The voltage applied across the voltage coil is the difference between the lines R and Y; that is the difference between phasors VRN and VYN i.e. the phasor VRY. The phase-angle between VRY and –VYN is 30°, for a balanced system, and that between –VYN and VBN is 60°. Thus the total phase-angle difference between VRY and VBN is 90° and the angle between VRY and IB is (90° + Φ). The wattmeter will read

Where, V is the per phase rms voltage and I is the line current of the system.

The total reactive power of the circuit is therefore

One thought on “Power Measurement in AC Circuits (Single-phase & Polyphase Systems)”